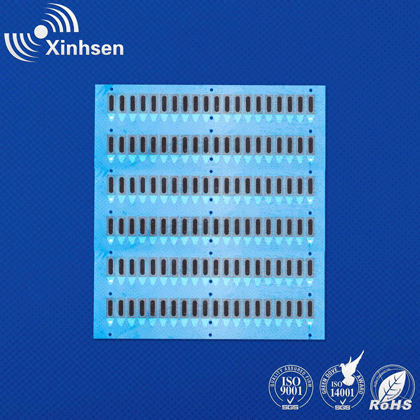

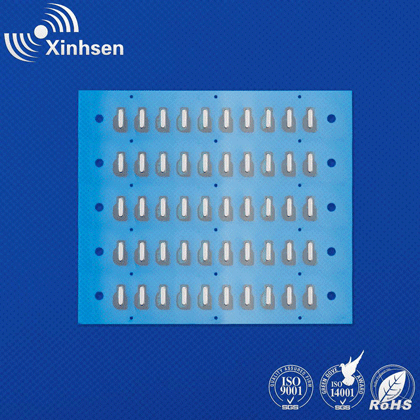

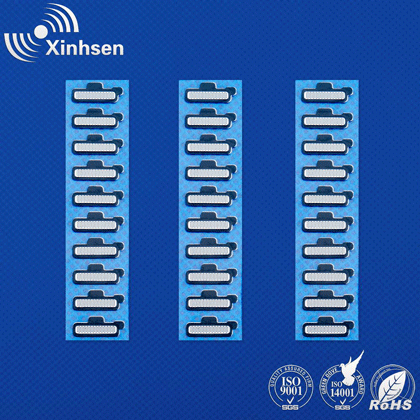

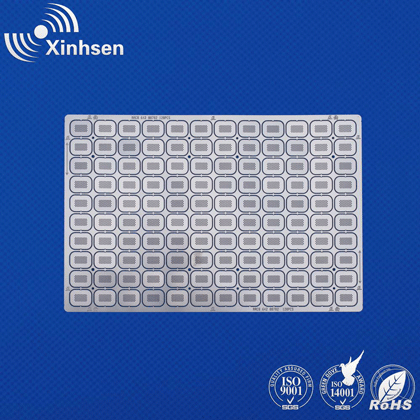

Photo etching is widely used in ear speaker anti-dust mesh making, especially for cell phone, as the technique achieves micro and precision metal meshes. Hysonetch photo etching can not only make the required mesh but also offer the self adhesive for the mesh plate.

Why photo etching?

1, Achieve precision and micro parts easily

2, Much flexibility on design

3, Various options on material

4, Burrs and stress free

5, Low cost and fast for sampling

Photo reference:

|  |  |  |

Product advantage:

1. Low cost for sampling and product development including 3M adhesive

2. Densely micro holes according to your requirements.(holes can be as small as 0.05mm)

3. Accurate aperture shapes / sizes to gurantee well match with the devices

4. More flexible on mesh design: Special features and differing aperture shapes can be incorporated in a single mesh without cost penalty

5. Wide range on material option: Xinhaisen photo etching can make meshes on Stainless steel, Copper, Brass, Aluminum, Carbon Steel, Titaninum, metal alloy and so on, from 0.02mm to 1.0mm thick, sizes up to 1500mm x 600mm

6. More options on required process: photo etching metal mesh also can be plated, stamped to shape and logo added

7. Stress and burr free, no sharp edge

8. Standard and high capacity adhesive and assembly production line with Dust-free workshop

Why partner with Hysonetch:

10 years focus on precision metal components with photo etching

Professional engineer team and experienced workers

Advanced production line and machines

Dust-free packing room

Trained QC team

100% fully check before shipment

Free manufacturing consultant

Not sure if your parts can be photo etched? Please feel free to contact us now, Free Quote can be sent within 24 hours