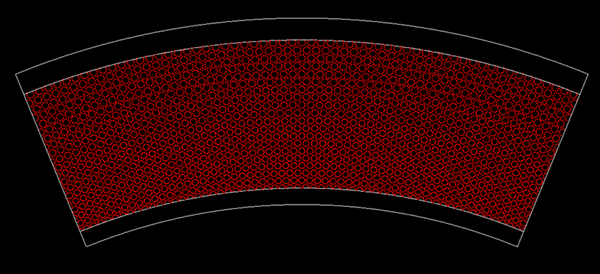

Good tea filters require good filter mesh, with photo etching, you can get what you want.

Tea lovers want their tea brewed better and better, then tea pot or tea filter manufacturers start looking for better solution for better filter meshes. Besides the well appreance, they requires smaller and plenty of holes, so the water can go through the tea leaves totally and the tea filter can keep the dregs inside as much as possible. Photo etching is definitely the best choice to meet this demand on mesh making.

Advantages of photo etching:

1, Micro and precision: Photo etching can achieve lots of micro holes on small metal plate, can make your tea filter mesh much fine and precision

2, Much flexibility on design: No matter the hole pattern or the pattern on the mesh plate, photo etching allows much room for your imagination

3, Fast sampling: 3-5 days to finish the mesh making will help you speed up your products development

Photo reference:

|  |  |  |

Design Guide:

1, Material: 304 stainless steel (Food grade)

2, Size: 1*1-600*700mm2

3, Thickness: 0.1-0.3mm for tea filter mesh

4, Holes: normally is 0.45mm +/- 0.05mm, but can be customized according to your requirements

5, Hole patterns: get use of your imagination, photo etching allows much flexibility on design

6, Surface finish: polishing, brushing, plating

Why partner with Hysonetch:

10 years focus on precision metal components with photo etching

Professional engineer team and experienced workers

Advanced production line and machines

Dust-free packing room

Trained QC team

100% fully check before shipment

Free manufacturing consultant

If you are not sure whether your parts can be photo etched, please feel free to contact us, our professional engineer team is waiting for you. Get A Free Consultant Now